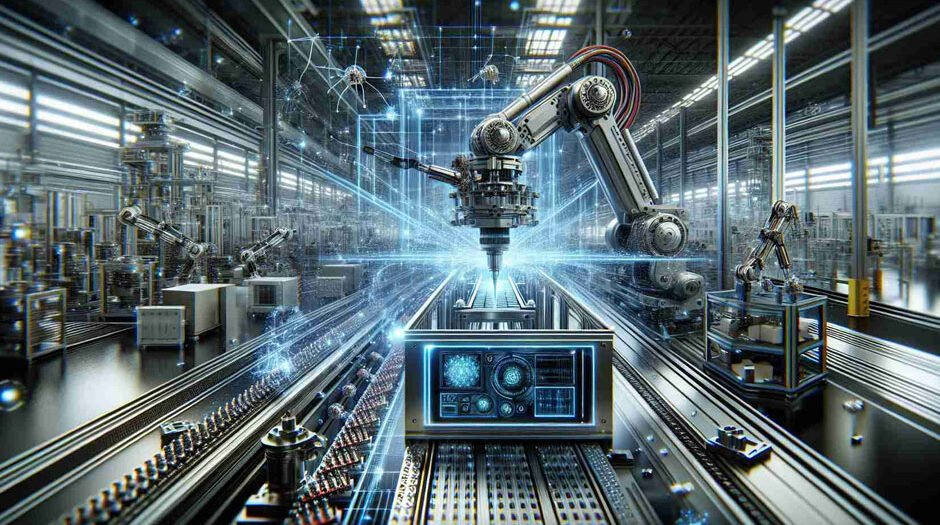

In the resurgence of vinyl records, manufacturers are turning to industrial automation to meet the increasing demand for this nostalgic medium. The integration of sophisticated technologies like servo drive controllers has transformed vinyl production from a largely manual process to one marked by precision, efficiency, and scalability. This article delves into the role of industrial automation in vinyl manufacturing, exploring how these technologies are reshaping the industry.

The Vinyl Manufacturing Process

Manufacturing vinyl records is an intricate process that involves several key steps: mastering, plating, pressing, and packaging. Each stage must be precisely controlled to ensure the final product meets high-quality standards, which is where industrial automation comes into play.

- Mastering and Plating: The process begins with mastering, where audio files are converted into a physical master disc. Automation in this phase involves using precision cutting equipment to engrave audio grooves onto a lacquer-coated aluminum disc. This master is then used to create a stamper through an electroplating process. Automation ensures that the delicate grooves are accurately replicated during plating, maintaining the audio integrity.

- Vinyl Pressing: This is the core of vinyl production where the actual records are pressed. Automated hydraulic presses equipped with heating and cooling systems mold vinyl pellets into discs using the stampers created in the plating process. Here, servo drive controllers play a crucial role by regulating the speed and pressure of the presses to ensure consistent thickness and quality across batches. The precise control offered by servo drives helps avoid production errors such as vinyl warping or incomplete pressing, which are critical in maintaining the acoustic properties of the records.

- Quality Control and Packaging: Once pressed, records undergo automated inspection for any defects like non-fill or scuffs. Automated systems, often equipped with high-resolution cameras and sensors, scan each record, ensuring that only those meeting quality standards move to the packaging phase. Packaging itself is automated to handle large volumes efficiently, involving shrink wrapping and labeling before the records are ready for distribution.

Benefits of Industrial Automation in Vinyl Manufacturing

- Enhanced Precision and Quality: Automation brings unparalleled precision to the vinyl manufacturing process. Servo drive controllers, for instance, ensure that press machines operate with exact force and timing, critical for producing high-quality records. This level of precision reduces the rate of defective products and ensures customer satisfaction with every purchase.

- Increased Production Speed: Automated systems can produce records much faster than manual methods. This increase in speed is essential for keeping up with the market demand, especially given the recent resurgence in vinyl popularity.

- Scalability: Automation makes it easier for vinyl manufacturers to scale their operations. As the demand fluctuates, automated systems can be adjusted more quickly than manual ones, allowing manufacturers to efficiently manage production volumes without compromising quality.

- Reduced Labor Costs: While the initial setup for automated systems can be costly, the long-term reduction in labor costs is significant. Automated machines reduce the need for manual labor in tasks that are repetitive and physically demanding, allowing human workers to focus on more critical areas like quality control and machine maintenance.

Challenges and Future Directions

Despite its benefits, the integration of automation in vinyl manufacturing presents several challenges:

- High Initial Investment: The cost of implementing automated systems, especially those involving advanced technologies like servo drive controllers like the DKC02.1-040-7-FW, can be substantial. Small to medium-sized enterprises may find the capital outlay prohibitive without financial assistance or strategic investment planning.

- Maintenance and Upkeep: Automated systems require regular maintenance to operate efficiently. The complexity of these systems demands skilled technicians who can troubleshoot and maintain them, adding to operational costs.

- Balancing Tradition and Technology: In industries like vinyl manufacturing, where the product is often valued for its traditional and nostalgic appeal, integrating too much modern technology can sometimes be seen as detracting from the authenticity of the product. Manufacturers must balance the use of automation with the preservation of the traditional qualities that appeal to vinyl enthusiasts.

Conclusion

Industrial automation, powered by advanced technologies such as servo drive controllers, is transforming vinyl manufacturing, making it possible to meet modern demands while maintaining the quality and character that vinyl records are known for. As the industry continues to grow, the challenge will be to further integrate these technologies in ways that enhance productivity and sustainability without compromising the unique qualities of vinyl records. This evolution in manufacturing will likely continue to innovate, ensuring vinyl’s place in the future of music consumption.